What is experimental design?

The first post in the DoE demystified series introducing experimental design

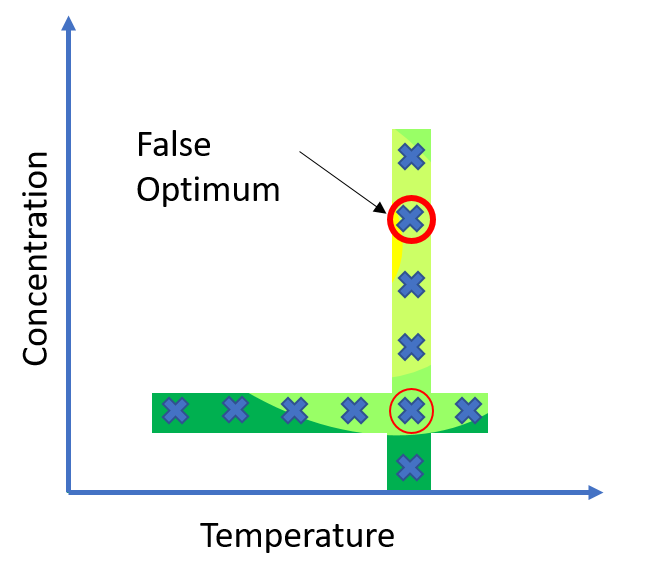

Traditionally, chemists investigate a reaction by focussing on one variable at a time (OVAT). For example, by setting a concentration and varying the temperature until the greatest conversion is achieved, then holding at that temperature and varying the concentration to see if there is an effect. Based on varying these two parameters a 'false optimum' is found. This process generally requires a large investment in time and resource, especially when a multi-component or catalytic process is in need of optimisation. Additionally, a true optimisation is never achieved when experimenting in this fashion as interactions between factors are missed and only a cross-section of the chemical space is investigated (see below left). The true potential of the system will not be uncovered.

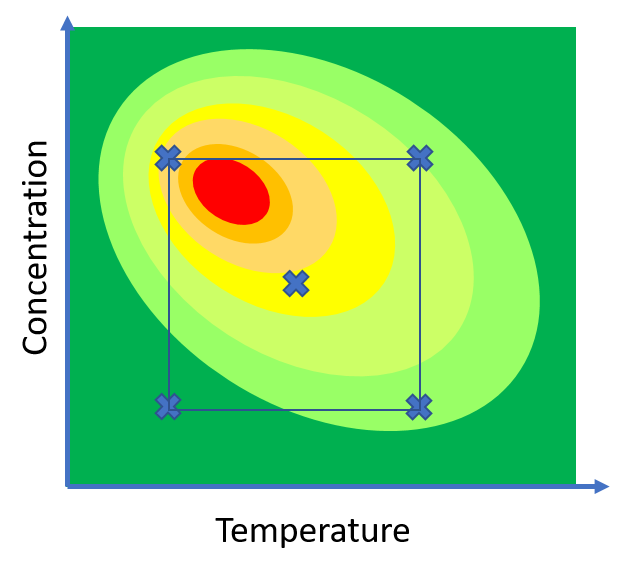

Design of experiments (DoE, also known as statistical or factorial experimental design) is a more effective experimental technique which involves planning, conducting and interpreting a set of controlled experiments, where multiple factors (conditions which will affect the reaction) are varied simultaneously. It enables scientists to examine the effect of each factor on a measured response and is able to interpret the combined effect that 2 or more factors have on the response (an interaction). This increased knowledge is obtained through the use of statistics: mathematical models are created to fit the experimental data. They can be used to determine: which factors have the biggest influence on any desired response, any interactions that are at play, and how to optimise the response based on the factors involved.

To perform a successful design, you must initially consider all the possible factors in the reaction under question then whittle these down to the ones which are expected to affect the outcome. This can be done by prior knowledge or literature knowledge and confirmed with sighting experiments. Once the important factors are selected, the levels at which they are investigated are chosen. The factors are all investigated at high and low levels to cover a large area of the experimental space (see above right). A clear direction of travel is given and a heat map or contour plot can be generated showing the potential areas of greatest conversion.

A well-performed design requires fewer experiments than OVAT, reducing the time required and increasing throughput. It increases understanding of the total experimental space, gives an overview of how the total system works, and provides an idea of the experimental error. The inclusion of 3 repeat experiments in a design (centre points) allows the experimental error of the reaction to be calculated. This is not possible with the OVAT methodology unless each experiment is performed in duplicate or triplicate.

A good design should include all the important factors. If an important factor is not being controlled or is not investigated in the correct region, information obtained from the model could be wrong, or it may not be possible to create a model. The response being measured should be quantified accurately and should be measured close to the reaction i.e. before a challenging work-up rather than after. It is also important to select the correct design type for what you want to achieve. Different designs are available for screening, optimisation, and robustness purposes and should be used for the correct cause. More information on factor selection and design types will be made available in due course.

Hopefully this short post has provided you with an overview of experimental design and its benefits. For any questions get in touch with us through the contact tab, or LinkedIn.